Silo Fires can pose a severe threat to a facility as they can cause dangerous consequences if not properly handled, even leading to gaseous explosions with an unsafe atmosphere. By implementing an inert gas purge approach, specifically with nitrogen, the silo is able to return to safe levels and eliminate these scary risks.

Elements that contribute to silo explosions and fires

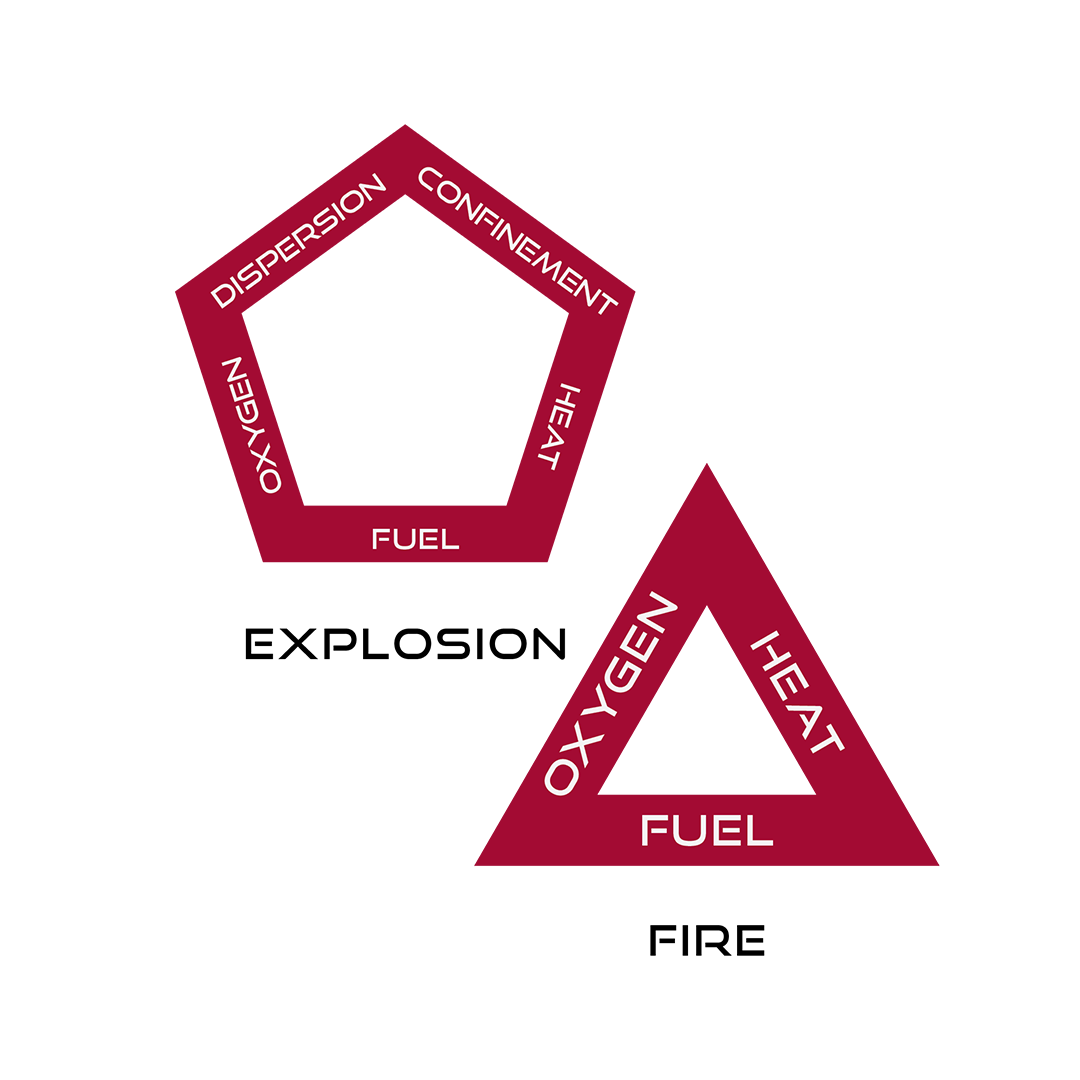

Elements that contribute to silo explosions and fires

Oxygen

Silos, storing grains and other materials, naturally contain oxygen. This element becomes a critical factor in the event of a fire, as it supports combustion and contributes to the potential for explosions.

Heat

The heat generated during a fire is another crucial element in the explosion equation. It accelerates the combustion process and can lead to the ignition of combustible dust.

Fuel

Grains and other materials stored in silos serve as fuel sources. These materials can become highly combustible, especially in the form of dust, contributing to the risk of explosions.

Dispersion and Confinement of Dust and Off Gases

The dispersion and confinement of combustible dust within the silo create an environment conducive to explosions. Fine particles suspended in the air can ignite rapidly, leading to a chain reaction.

Gasses such as Methane, Ammonia, Hydrogen, and other combustible elements also pose a serious role in the risk of explosions. These elements all contribute to the LEL, or lower explosion limit, of the atmosphere. Our crew is equipped with the knowledge and experience to know what levels each of these should be at, and how to control them to eliminate the risk of complications.

Silo Challenges and Obstacles

Silo Challenges and Obstacles

The most common silo storage material is grains, which predominantly consist of aerobes. This characteristic introduces a challenging balance of atmospheric levels, as oxygen is inherently present and plays a crucial role in supporting combustion. Achieving the right atmospheric balance in silos becomes crucial to prevent catastrophic events. The challenge lies in managing oxygen levels to minimize the risk of explosions while maintaining optimal conditions for stored materials.

Why Use Inert Gas Purging?

Inert Gas Purging emerges as a proactive and effective solution to the inherent risks associated with silo fires. By eliminating oxygen in the atmosphere, this method disrupts a crucial element in the explosion equation. Without an adequate supply of oxygen, the potential for combustion and subsequent explosions is significantly reduced.

Our Capabilities

IA Bulk Material’s Crews are equipped to tackle it all. Our phone line is open 24/7, 365 days a year to always be available for our trusted customers in their times of need. We offer emergency mobilization to quickly get to your site and handle the situation for you. We will assess the current atmosphere, locate where smolder or fire resides, bring our own NPU System to take control of the atmosphere, and then empty the silo for complete commodity removal. We are here for every step of the process until your operations are back to normal.