Rotary Kiln Solutions For Buildup

IA Bulk Materials is a complete ring management contractor providing expert solutions to removing ring buildup and blockages in rotary kilns. We implement routine maintenance solutions, such as Cardox blasting, Kiln Guns, and or mechanical equipment, to manage ring buildup and ensure minimal interruptions to operations. Regular buildup mitigation will eliminate forced shutdowns and maximize production efficiency with minimum upkeep.

Maintenance Plans

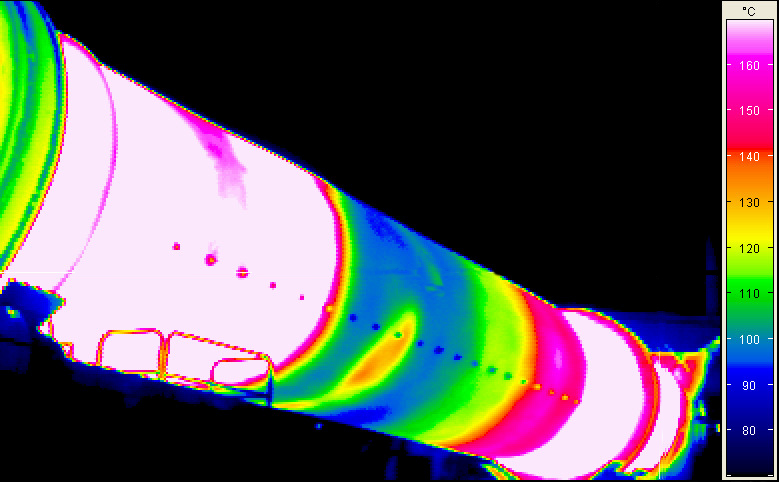

BEFORE Cardox Implementation

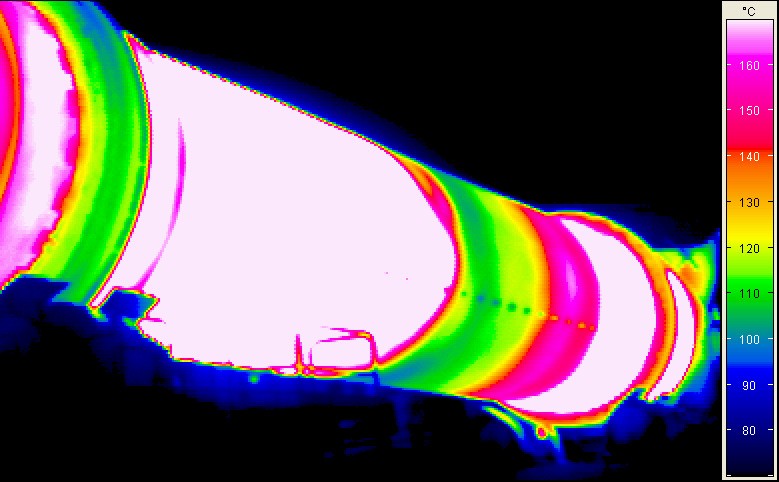

AFTER Cardox Implementation

How The Process Works

To clear these kiln rings, IA Bulk utilizes Cardox Blasting to keep the material flowing. We are able to use any ATD, Power Shot, or FV cardox systems you may have on site, or have the capability to provide this on our own.

After arriving on site, we perform a kiln assessment to find where the buildup ring is located. From there, we can install cardox ports on the side of the kiln to insert the cardox tubes. Finally, we then strategically blast through the ports until the buildup is cleared.

It is imperative to do this routine cleaning every 90 days. This ensures the rings don’t choke off your production flow. By waiting, you risk a possible plant shutdown, as well as a longer job to perform the cleaning. By routinely servicing your kiln, it ensures minimal downtime, and will save you money in the long run.

It is imperative to do this routine cleaning every 90 days. This ensures the rings don’t choke off your production flow. By waiting, you risk a possible plant shutdown, as well as a longer job to perform the cleaning. By routinely servicing your kiln, it ensures minimal downtime, and will save you money in the long run.

Whether you need regular maintenance on your kiln or clean out of rings or heavy coating due to long use without cleaning, Industrial Access Bulk Material can help. We ensure minimal downtime and effective solutions because we know that time is money for your company. By using one or more of our clean-out methods, your company’s assets will flow as usual quickly after we start the process.